With the rapid development of the oil and gas industry, the demand and technical requirements for valves have increased significantly. In order to meet the market demand, our company has introduced advanced automatic surfacing technology and equipment, and increased the investment in scientific and technological research and development, so that the scientific and technological content of Eu-Italy products has become the core competitiveness.

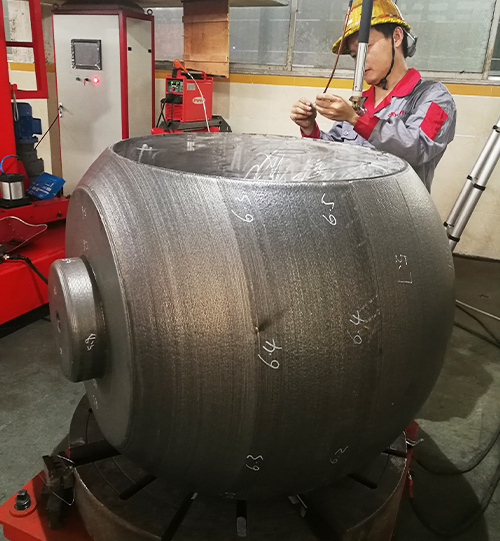

At present, the company has 6 large and small brand welders, which can be applied to the ball, valve body, valve cover, valve seat, sealing sleeve, valve stem and other parts. Can cover size range: DN50~DN1400 (2 "~56").

Our surfacing products are easy to control the shape of the surfacing layer, stable arc, no splash, good quality of the surfacing layer. To provide customers with complete solutions and cost optimization support!

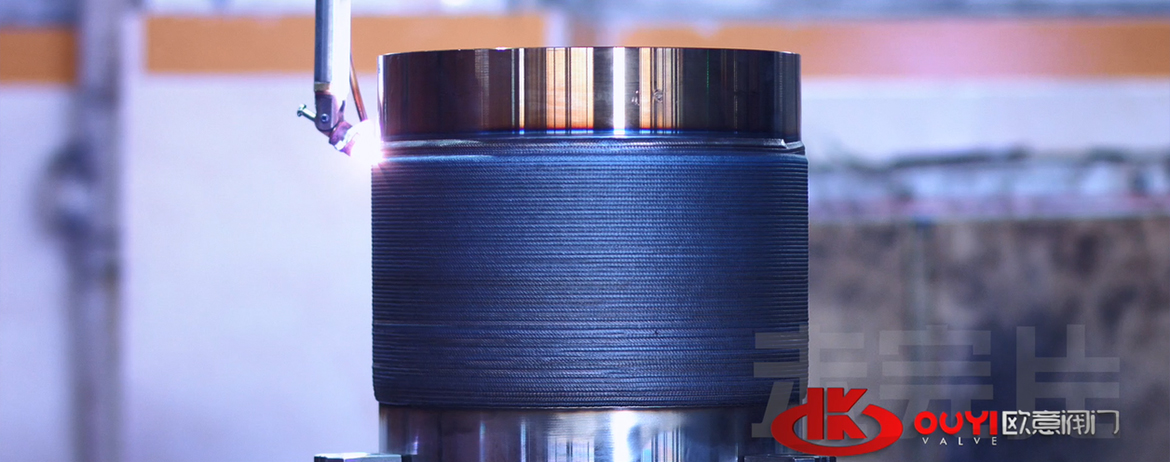

At present, our company adopts hot wire argon tungsten arc welding process and has successfully passed the surfacing process evaluation and welder's skill qualification evaluation for the following material.

LF2 reactor INCONEL625, LF2 reactor 316L, LF2 reactor INCONEL825. The whole process is witnessed and audited by well-known international tripartite TUV.

Welcome to inquire!