Product Categories

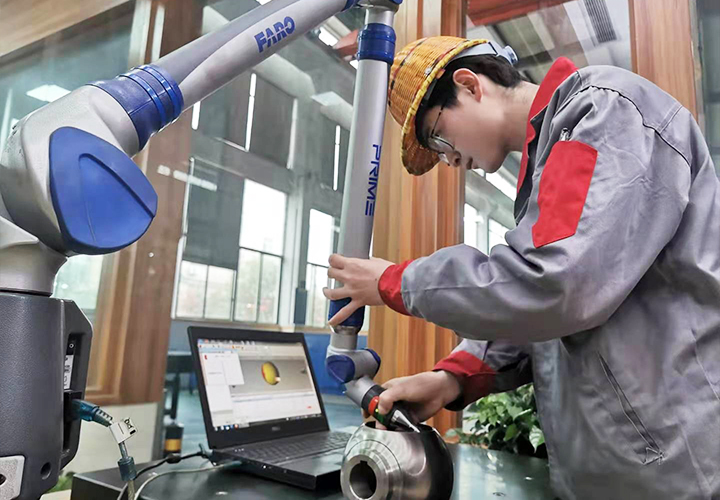

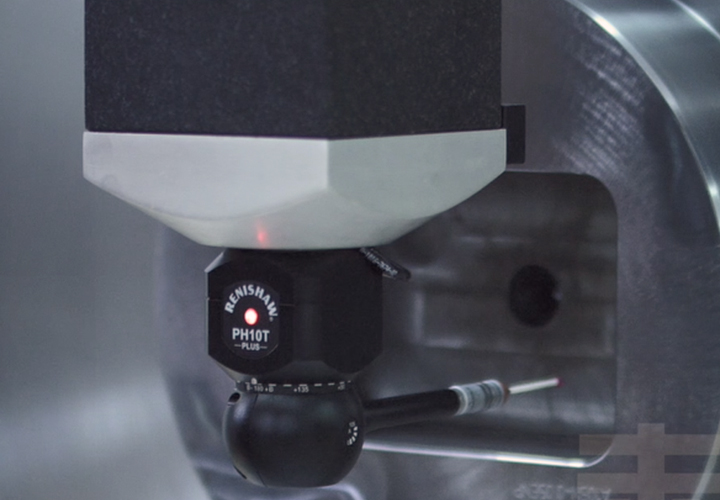

First grade equipment means the First Level products! Nowadays we owned machining equipment over 100 units, including CNC machining center over 10 units, common CNC over 30 units. To meet customer request to super size balls, OUYI customized & imported 64" & 24” ball machining & grinding integrative CNC to cover the vacancy of domestic large equipment capacity.

Read More